How to Choose the Right Dredge Manufacturer for Your Project: A Comprehensive Buyer’s Guide

Starting a dredging project means making many important choices. One of the most critical decisions is selecting the right dredge manufacturer. Your project’s success often depends on finding a partner who understands your needs and can deliver reliable, efficient equipment. This guide will help you navigate the process, ensuring you pick a manufacturer that provides long-term value and support.

Selecting the ideal dredge manufacturer is paramount for project success. It’s not just about buying a machine; it’s about investing in a solution that’ll perform under tough conditions and deliver consistent results. A good manufacturer will offer quality, innovation, and excellent support.

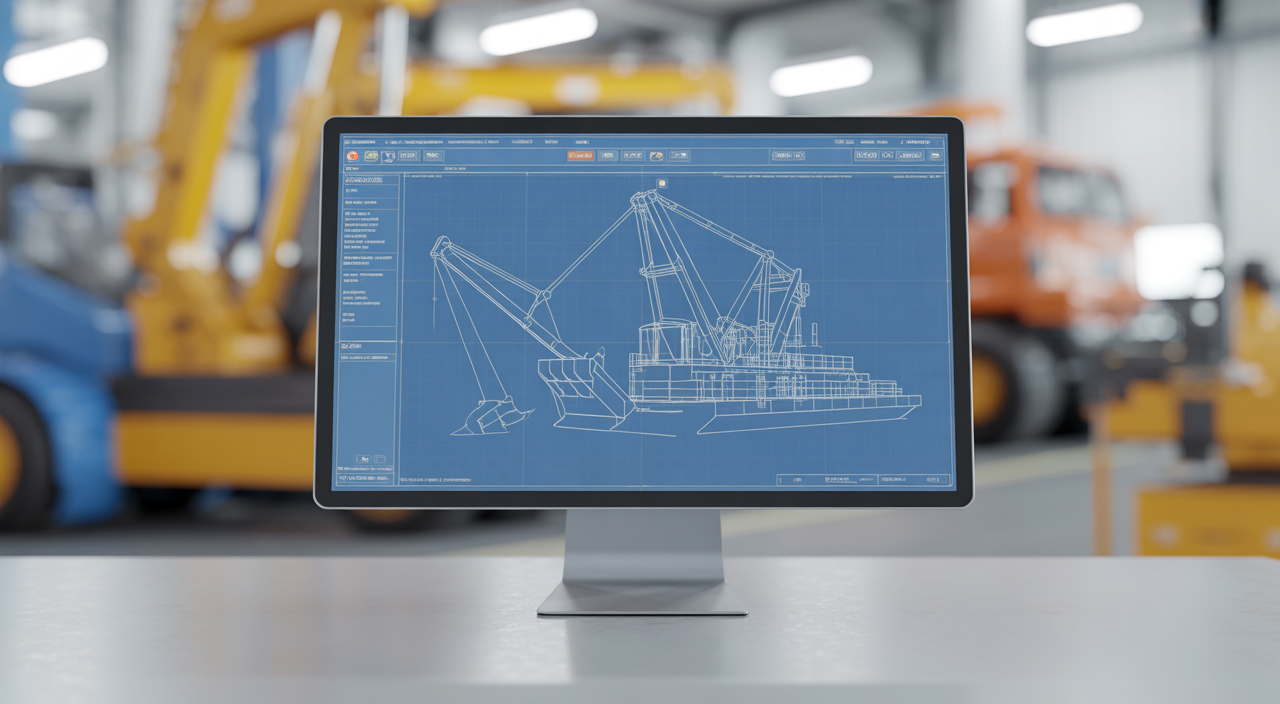

What Exactly Does a Dredge Manufacturer Do?

A dredge manufacturer does much more than just build machines. They’re involved in the entire process from start to finish. This includes designing, engineering, fabricating, and testing complex dredging equipment. They also often provide crucial after-sales support.Manufacturers specialize in different types of dredges. These can include hydraulic dredges, mechanical dredges, and cutter suction dredges. Their role extends to developing new technologies and innovative solutions. This helps make dredging operations more efficient and environmentally friendly.

Key Factors to Evaluate in a Dredge Manufacturer

When you’re looking for a dredge manufacturer, several key factors should guide your decision. These elements ensure you choose a partner that meets your technical and operational needs. They also help secure your project’s long-term success.

Experience & Reputation

How long has the manufacturer been in business? A company with a long history often brings deep knowledge and a proven track record. Look for their past projects and client testimonials. These can offer valuable insights into their reliability and performance. Industry certifications and adherence to global standards also show their commitment to quality.

Range of Equipment & Customization Capabilities

Does the manufacturer offer a variety of standard models? Can they provide bespoke solutions tailored to your unique project? Some projects, like those in shallow waters or with limited access, need highly specialized equipment. For projects specifically involving a dredge manufacturer – such as maintaining rivers, canals, ports, or marinas – a specialized manufacturer offers tailored solutions. These are designed for optimal efficiency and environmental compliance.

Technology & Innovation

Modern dredging demands advanced technology. Look for manufacturers who prioritize efficiency, automation, and sophisticated control systems. Their commitment to research and development (R&D) is key. This means they’re always incorporating new materials and techniques. Technologies like GPS positioning, remote control capabilities, and detailed data monitoring can greatly improve project outcomes.

After-Sales Support, Parts, and Training

Equipment needs ongoing support. A reliable manufacturer will offer accessible spare parts and service centers. These should ideally be available in your region or globally. Technical support and troubleshooting assistance are also vital. They’ll help minimize downtime. Furthermore, effective operator training programs ensure your team can use the equipment safely and efficiently. If you’re considering used dredging equipment, checking the availability of parts and support becomes even more critical.

Safety & Environmental Compliance

Safety should always be a top priority. Ensure the company adheres to strict safety standards in both design and operation. Environmental concerns are also growing. Look for dredges designed for minimal environmental impact. This includes features for low turbidity (less cloudiness in water) and precise cuts. A good manufacturer will understand and help you meet local and international environmental regulations.

Total Cost of Ownership (TCO) & ROI

The purchase price is just one part of the equation. Consider the total cost of ownership (TCO). This includes fuel efficiency, maintenance costs, and the expected lifespan of the equipment. A robust design and reliable support can significantly reduce downtime. This translates to lower operational costs. A quality dredge manufacturer provides long-term value and a strong return on your investment (ROI).

Types of Dredges and Their Ideal Applications

Understanding different dredge types helps you choose the right equipment. Each type is best suited for specific tasks and environments.

- Cutter Suction Dredges: These dredges have a rotating cutterhead at the suction inlet. They break up hard materials like compacted sand, clay, or rock. They’re often used for general excavation in harbors and navigation channels.

- Hydraulic Dredges: These machines use powerful pumps to suck up loose materials like mud, silt, and sand. They’re highly efficient for moving large volumes of soft sediment over long distances through pipelines.

- Mechanical Dredges: Mechanical dredges use buckets or grabs to dig and lift material. They’re effective for removing heavy debris, large rocks, or working in areas with restricted access. Examples include grab dredges and backhoe dredges.

- Portable & Specialty Dredges: These are smaller, often modular dredges. They’re designed for specific niches like shallow water operations, industrial ponds, or remote locations. They’re easy to transport and assemble. If you’re looking at dredging equipment for ponds, a portable dredge might be ideal.

A good manufacturer will offer the right tool for specific needs. They’ll guide you in selecting the best type for your diverse waterway scenarios.

How to Conduct Your Due Diligence: A Buyer’s Checklist

Before making a final decision, thorough research is key. Use this checklist to evaluate each potential supplier.

- Request Detailed Specifications: Ask for comprehensive data on performance, capacity, and technical features.

- Ask for Client References: Speak with other customers about their experiences. Ask for examples of similar projects they have completed.

- Inquire About Warranty and Service Agreements: Understand what’s covered and for how long. Clarify service terms and response times.

- Understand Lead Times: Confirm manufacturing and delivery schedules. It’s crucial for project planning.

- Visit Facilities (if possible): A factory visit can provide insights into their quality control and production processes.

- Check Financial Stability: A stable company’s more likely to provide long-term support and honor warranties.

- Evaluate Communication: Assess how responsive and clear their communication is during the inquiry process.

This checklist will help you evaluate each prospective supplier thoroughly. It ensures you cover all important aspects.

Conclusion: Partnering for Dredging Success

Choosing the right dredge manufacturer is a significant decision. It impacts your project’s efficiency, cost-effectiveness, and environmental footprint. By carefully evaluating experience, technology, support, and long-term value, you can select a partner that ensures success.The right partner provides reliable equipment and comprehensive support. This leads to smooth operations and long-term project success. Ready to discuss your next project? Explore trusted waterway dredging systems and connect with experts today to find a solution tailored to your needs.

Frequently Asked Questions (FAQs)

Q1: How important is customization when choosing a dredge?

A1: Customization is very important, especially for unique projects. Standard dredges might not always fit specific water depths, sediment types, or environmental regulations. A manufacturer who can customize equipment ensures optimal performance and efficiency for your exact needs.

Q2: What is “turbidity” in dredging, and why is it a concern?

A2: Turbidity refers to the cloudiness or haziness of a fluid caused by suspended particles. In dredging, high turbidity means more sediment is stirred up into the water. This can harm aquatic life, impact water quality, and violate environmental regulations. Modern dredges are designed to minimize turbidity for eco-friendly operations.

Marin Hùng, a passionate advocate for holistic well-being, is the driving force behind our health-focused platform. With a deep-rooted commitment to promoting a balanced and vibrant lifestyle, Marin brings a wealth of knowledge and experience to our health community. As a dedicated writer and wellness enthusiast, Marin’s insightful articles and expertise are at the heart of our mission to inspire healthier living.

Post Comment